DEMAGNETISING COILS

Demagnetising Coils have been developed to demagnetise Magnetite and Ferro-magnetic medium flowing in a slurry through vertical pipelines, as in the case of concentrate exiting from a Wet Drum Magnetic Separator.

Demagnetising Coils are available in internal diameters of 4, 5, 6, 8 & 10 inch. Various other sizes are available on request.

DEMAGNETISING COILS

Demagnetising Coils have been developed to demagnetise Magnetite and Ferro-magnetic medium flowing in a slurry through vertical pipelines, as in the case of concentrate exiting from a Wet Drum Magnetic Separator.

Demagnetising Coils are available in internal diameters of 4, 5, 6, 8 & 10 inch. Various other sizes are available on request.

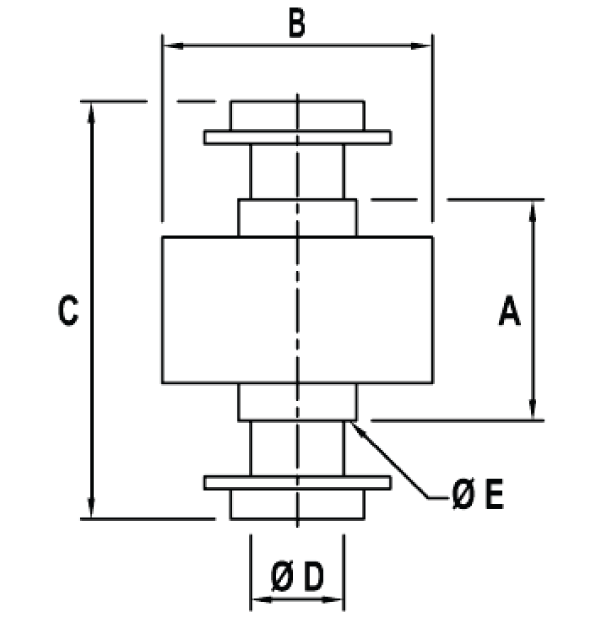

construction

The coils, made from varnished copper wire which is

wound around a bobbin, are protected from moisture

ingress and physical damage by epoxy resin and laser

cut stainless steel guards.

The bobbin is made from electrical grade non- metallic

material. The coil winding is suitable for operating

temperatures of 80° to 95° C and is protected from

overheating by thermistors wound into the coil.

The thermistors have a maximum cut-off point,

pre-set at 105° C and are terminated in an I.P. 55

terminaI box.

A separate (Optional) HDPE pipe is used to transport

the slurry medium through the centre of the coil.

General

Whilst demagnetising coils are relatively maintenance

free, they should be inspected regularly to ensure they

are free of mechanical damage.

If any debris (magnetic / non-magnetic particles) have

collected between the bobbin and the pipe conveying

the slurry, these must be removed. The magnetic slurry must not be allowed to solidify within the slurry line passing through the demagnetising coil.

INSTALLATION

The demagnetising coil must be mounted so that the pipe

conveying the slurry which is to be demagnetised passes

through the centre of the coil. The pipeline conveying the slurry medium must be of non-metallic material i.e., HDPE, plastic or rubber etc. As the unit is uniform in design, either end can be used as the in let. The demagnetising coil can be suspended using wire ropes slings or by flanging the slurry line directly to the (Optional) HDPE pipe.

All Connetions are made via a waterproof terminal box

mounted on the underside of the coil. The thermistors

may be connected to a thermistor relay. Failure to

connect in conjunction with a thermistor relay will

eliinate any form of overheating protection and may

result in possible damage to the coil. The demagnetising

coil should be mounted / suspended in such a way that it

is protected from falling objects or splashing water.

INSTALLATION

The demagnetising coil must be mounted so that the pipe

conveying the slurry which is to be demagnetised passes

through the centre of the coil. The pipeline conveying the slurry medium must be of non-metallic material i.e., HDPE, plastic or rubber etc. As the unit is uniform in design, either end can be used as the in let. The demagnetising coil can be suspended using wire ropes slings or by flanging the slurry line directly to the (Optional) HDPE pipe.

All Connetions are made via a waterproof terminal box

mounted on the underside of the coil. The thermistors

may be connected to a thermistor relay. Failure to

connect in conjunction with a thermistor relay will

eliinate any form of overheating protection and may

result in possible damage to the coil. The demagnetising

coil should be mounted / suspended in such a way that it

is protected from falling objects or splashing water.

PRODUCT

RANGE