PERMANENT MAGNETIC PULLEY

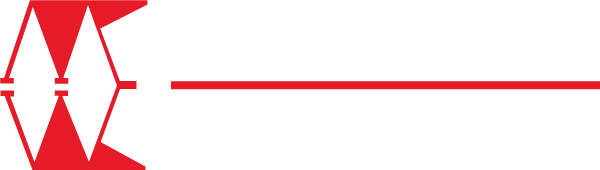

Ceramic magnets are used for these special application magnetic pulleys. The magnetic field extends over an arc of the pulley and not the entire circumference and is stationary. A vibratory feeder can be optionally offered for feeding the separation belt. The belt take up system, mild steel frame, drives for the pulley would form part of the equipment supply as can be seen in the picture above. The equipment is available in diameters 500 to 1200 mm, for particle size ranging from 50 to 250 mm and capacity of 50 to 460 MTPH.

Removal of tramp iron and protection of downstream machinery

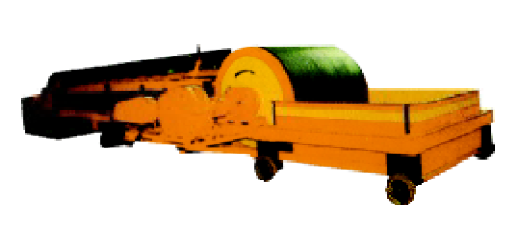

Permanent magnetic pulleys are ideally installed to replace the head pulley of a conveyor conveying dry material. The permanent magnetic pulley shell will be made of non-magnetic stainless steel and if necessary can be rubber lagged. The main information required for the selection of the magnetic pulley are:

- Belt Width.

- Belt thickness.

- Belt speed.

- Material being conveyed.

- Particle size of material being conveyed.

- Nature of tramp iron and size expected to be removed.

- Diameter and width of head pulley.

- Head pulley shaft diameter.

The magnetic field extends over the whole circumference of pulley. The magnet inside the shell rotates along with the pulley and is not stationary. The ferrous parts attracted are held within the belt contact area with the magnetic pulley until they are discharged on the bottom side of the pulley. Permanent magnetic pulleys are best used in conjunction with suspended electro or permanent magnets and the tramp iron buried under the burden of material being moved is more likely to be eliminated by the magnetic pulley.

For Ore Concentration (Cobbing) – (for magnetite ore)

Ceramic magnets are used for the construction of the permanent magnetic pulleys. However, for special applications, rare earth magnets too can be used and made available.