SAMPLING SOLUTIONS

Malvern Engineering specialises in the design and manufacture of sampling equipment for bulk materials and solids.

We offer:

- New sampling equipment.

- Rectification of problems in existing sampling equipment.

- Replacement of existing sampling equipment.

- Precision sampling equipment.

Malvern Engineering specialises in the design and manufacture of sampling equipment for bulk materials and solids.

We offer:

- New sampling equipment.

- Rectification of problems in existing sampling equipment.

- Replacement of existing sampling equipment.

- Precision sampling equipment.

VARIABLE SPLIT SAMPLE

DIVIDER (VSSD)

- Achieves mechanically correct division to a precise target mass in one step in a short time.

- Eliminates the need for manual sample mass division in sample preparation protocols, with minimum possible assay variance.

- Operation in stand-alone mode.

- Operation in Auto mode. It can be interfaced to your Laboratory Information Management System (LIMS) via a simple serial link. Commands comply with the ModBus protocol.

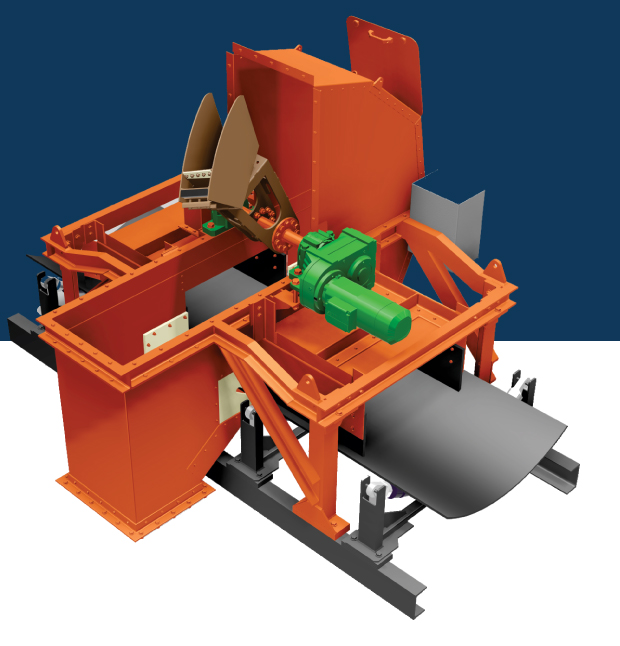

CROSS BELT SAMPLER /

HAMMER SAMPLER

- The Malvern Engineering Cross belt (or hammer) sampler has been robustly designed using the ISO 13909 standard as a basis for design.

- Designed with a double sweep/cleaning system which together with the flexible idlers supplied with the machine shapes the belt contour and ensures that a clean cut is taken.

- Servo controlled asynchronous servo-motor with minimum backlash.

- Flawless Belt tracking.

- Four Modes of Operation: Manual, Remote, Auto Timed, Inspection/Maintenance

Application

- Composite Sample Preparation

- Sample Testing for Metallurgical Tests

Interleaving sampler

- Extracts two nominally identical samples from a flow of dry free flowing material.

- Reliable means of providing an undisputable measure of sampling precision.

- Designed to have minimal hang-up.

- Dust tight Construction.

- Available with two drive options – a stepper motor drive system or a variable speed sensorless vector controlled, geared drive system.

- Advantageous when splitting high value stream.

- Stepper motor drive system allows more flexibility and can be programmed to extract different sample masses from the lot.

Interleaving sampler

- Extracts two nominally identical samples from a flow of dry free flowing material.

- Reliable means of providing an undisputable measure of sampling precision.

- Designed to have minimal hang-up.

- Dust tight Construction.

- Available with two drive options – a stepper motor drive system or a variable speed sensorless vector controlled, geared drive system.

- Advantageous when splitting high value stream.

- Stepper motor drive system allows more flexibility and can be programmed to extract different sample masses from the lot.

ROTARY SAMPLE

DIVIDER (RSD)

- Extremely reliable method for mass reduction of a sample.

- Large number of increments ensure that material segregation (distributional heterogeneity) in the starting sample is radically reduced in each of the subsamples.

- Heavy duty construction with a robust drive train that ensures constant speed throughout the splitting process.

- Minimises sample variance.

- Incorporates a state of the art feeder which ensures a constant flow of material to the splitting section, which can be calibrated per application to suit the relevant material being split.

- Sampling Capacity of standard unit: 15 Litres

- Division Ratio: 1:10