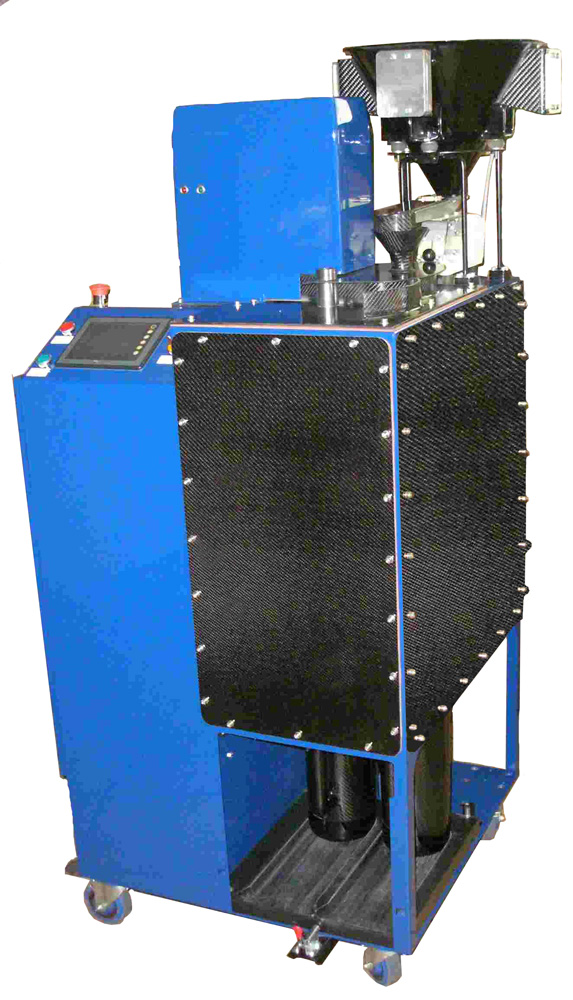

VARIABLE SPLIT SAMPLE DIVIDER

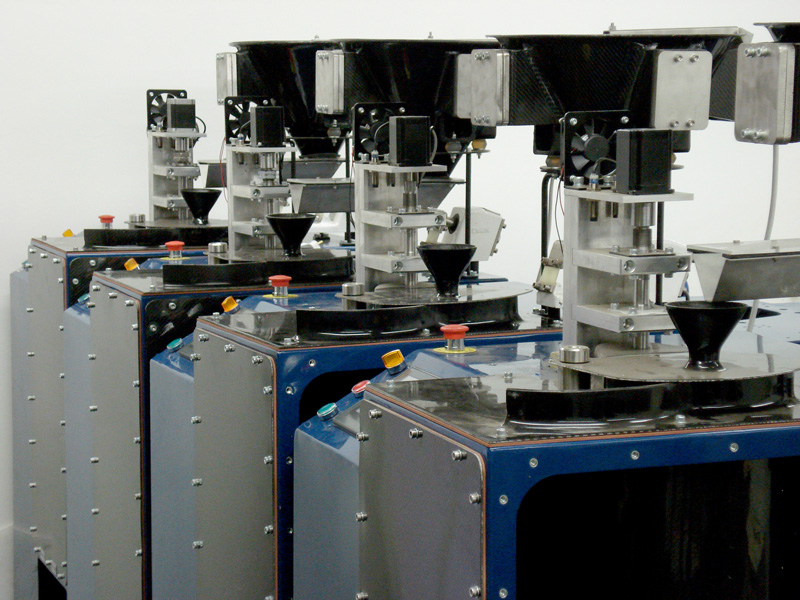

Mechanically correct sample division to a precise target mass in one quick step. Eliminates manual sample division to minimise sample preparation variance. The VSSD was developed specifically to permit elimination of manual sample mass division in sample preparation protocols for high value and difficult to handle streams.

VARIABLE SPLIT SAMPLE DIVIDER

Mechanically correct sample division to a precise target mass in one quick step. Eliminates manual sample division to minimise sample preparation variance. The VSSD was developed specifically to permit elimination of manual sample mass division in sample preparation protocols for high value and difficult to handle streams.

ACCURATE

SAMPLE SPLITTING

Mechanically correct sample division to a precise target mass in one quick step. Eliminates manual sample division to minimise sample preparation variance. The VSSD was developed specifically to permit elimination of manual sample mass division in sample preparation protocols for high value and difficult to handle streams. When subsamples need to be prepared to an accurate mass for subsequent aliquot preparation for weighted-composite sample make-up or metallurgical tests, the VSSD will do it quickly with the minimum possible assay variance. The patented design obeys every rule for mechanically correct division from a falling stream; the economy of motion of the cutter permits the division to be accomplished in the minimum possible time and with ultimate accuracy.

Even segregated precious metal concentrates for example can be confidently divided with the near zero sample variance. The VSSD makes splits from 5 to 95% of the original sample mass to within 1% of the target mass. The large number of increments taken essentially eliminates assay variance due to sample segregation.

The VSSD will split out a subsample of a target mass from a 3 kg sample in 5 minutes with a proven accuracy of 5 to 10 parts per thousand. Splits near 50% can be made within a minute. Daily composite sample preparation times when making use of the VSSD are reduced by a factor of 5. These reduced sample preparation times result in reduced labour costs and a very short payback period on the capital purchase.

Easy Operation Manual or Automated

The VSSD can be operated in a stand-alone manner (manual mode) or interfaced to a Laboratory Information Management System (LIMS) via a simple serial link (auto mode). Commands comply with the ModBus protcol.

With or without the LIMS being active, all operator cotrol of the sample division is made using an industrial grade Touchscreen with simple displays that take the operator through the division process as well as protect the sample integrity.

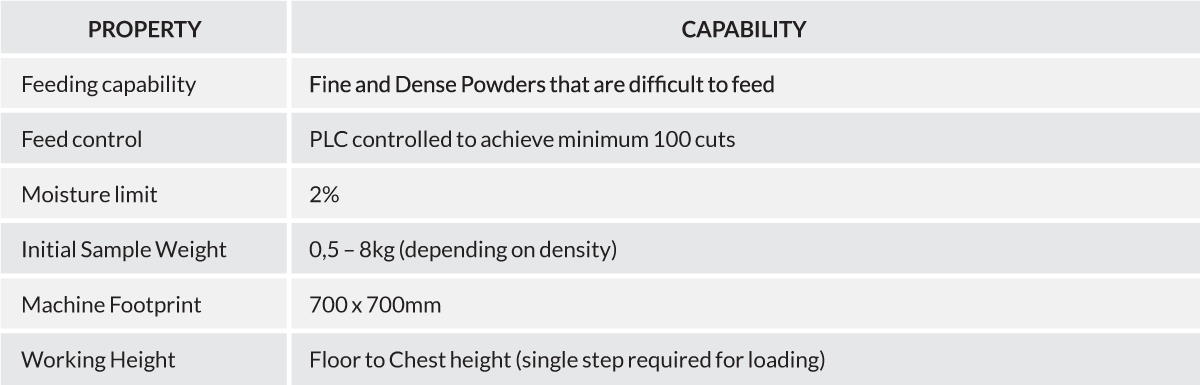

VSSD SPECIFICATIONS

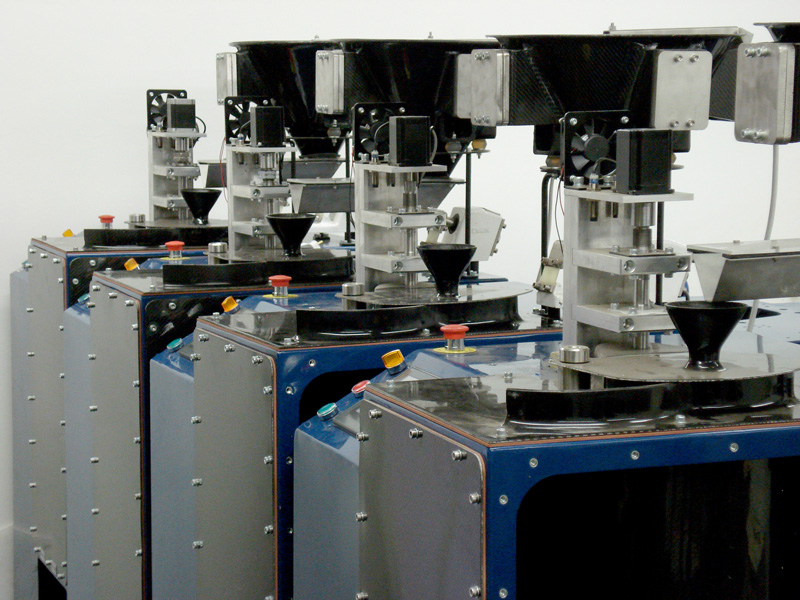

Rather than operating in a circular motion, which wastes time when dividing out a single subsample, the VSSD

oscillates back and forth through a falling stream of material. The cutter is controlled so that it can be paused while

the cutter is collecting the full stream of material or is collecting none of the material; this permits precise control of

the mass of the subsample calculated via the PLC. The cutter is directly driven by the PLC ensuring that the cutter

speed is constant while the cutter edges are passing through the stream. This fact ensures that the subsample is cut

out in a manner that is mechanically correct as per a conventional rotary divider.

Rather than operating in a circular motion, which wastes time when dividing out a single subsample, the VSSD

oscillates back and forth through a falling stream of material. The cutter is controlled so that it can be paused while

the cutter is collecting the full stream of material or is collecting none of the material; this permits precise control of

the mass of the subsample calculated via the PLC. The cutter is directly driven by the PLC ensuring that the cutter

speed is constant while the cutter edges are passing through the stream. This fact ensures that the subsample is cut

out in a manner that is mechanically correct as per a conventional rotary divider.

APPLICATIONS

The VSSD was developed specifically to solve the problem of making up composite samples to a fixed weight. Typically, a composite sample might be based on 3 to 10 starting samples. The objective is to make a mass-weighted composite sample of a final target weight. The VSSD provides the precise mass division that simplifies the subsequent sample preparation steps. Without the VSSD, mass division to a precise target mass must involve rotary division to a mass close to the target mass followed by ‘dipping’ of material from one of the remaining fractions from the rotary division.

Precious metal concentrates, and even base metal ores, are highly prone to segregation; the ‘dipping’ process will always increase the sample preparation variance or, worse, lead to a biased sample.

SAMPLE DIVISION FOR METALLURGICAL TESTS

Standard metallurgical tests, such as flotation tests, require that each sample for the test program be of a specific mass so that the percent solids in the pulp are the same every test. It is critical that each sample have, as far as possible, the same size distribution and the same size by size composition distribution with respect to all analytes of interest. The VSSD permits the extraction of entirely correct subsamples of a precise mass, eliminating a common source of variance from the test outcomes. The splitting is made simply, rapidly and correctly. The test fractions are as similar to each other as is possible, given the particulate nature of the material.

Any application that requires a precise mass of subsample would benefit from the use of a VSSD, this proven technology is found throughout the laboratories of multinational precious metals producers. This machine forms part of their standard operating practices and procedures and have revolutionised the accuracy of their outputs.

Standard metallurgical tests, such as flotation tests, require that each sample for the test program be of a specific mass so that the percent solids in the pulp are the same every test. It is critical that each sample have, as far as possible, the same size distribution and the same size by size composition distribution with respect to all analytes of interest. The VSSD permits the extraction of entirely correct subsamples of a precise mass, eliminating a common source of variance from the test outcomes. The splitting is made simply, rapidly and correctly. The test fractions are as similar to each other as is possible, given the particulate nature of the material.

Any application that requires a precise mass of subsample would benefit from the use of a VSSD, this proven technology is found throughout the laboratories of multinational precious metals producers. This machine forms part of their standard operating practices and procedures and have revolutionised the accuracy of their outputs.