WET WLIMS AND MLIMS

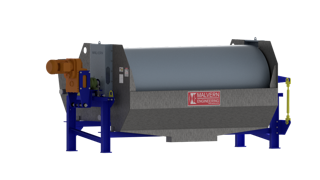

Malvern’s Wet Low Intensity Magnetic Separators (WLIMS) have evolved over the years as a result of a continuous process of innovation and product improvement.

WET LOW/ MEDIUM INTENSITY MAGNETIC SEPARATORS

Malvern’s Wet Low Intensity Magnetic Separators (WLIMS) have evolved over the years as a result of a continuous process of innovation and product improvement.

Our skilled and dedicated engineering and design team as well as customers have contributed largely to this process.

IMPROVED

PRODUCT DESIGN

Malvern’s Wet Low Intensity Magnetic Separators (WLIMS)

have evolved over the years as a result of a continuous

process of innovation and product improvement.

Our skilled and dedicated engineering and design team as well as customers have contributed largely to this process. The development process targeted improvement in tank designs, magnetic circuits and special features in the machine to allow for easy adjustment of the parameters affecting performance. Emphasis has also been given to the safety aspects and ease of adjustment of the machine while in operation.

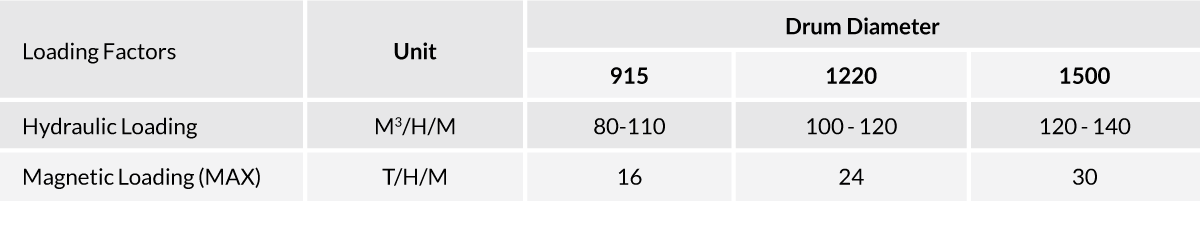

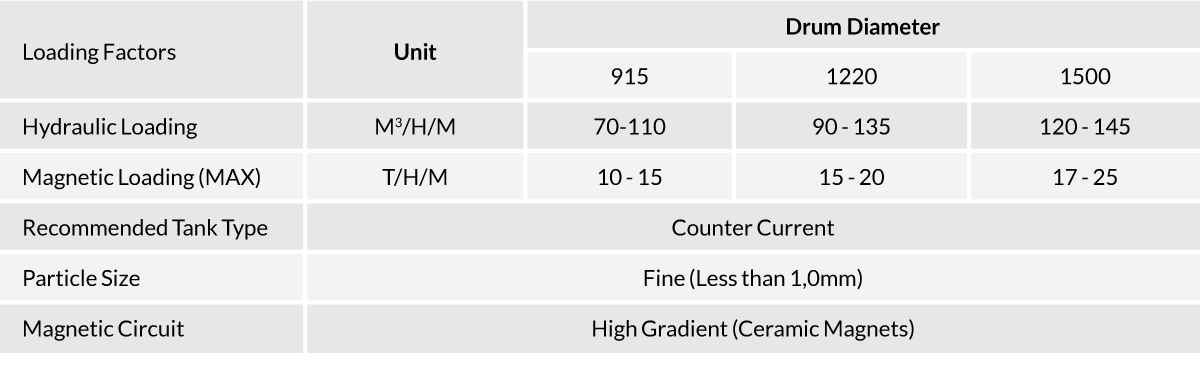

PRODUCT RANGE

APPLICATIONS

- Recovery of magnetite in heavy media applications for coal.

- Recovery of ferro-silicon in heavy media application for diamonds, iron ore, chrome.

- Scalping magnetic material from a feed to the WHIMS/HGMS – hematite/chrome.

- Cobbing application for iron ore concentration.

- Cleaner/re-cleaner and finisher application for ore concentration.

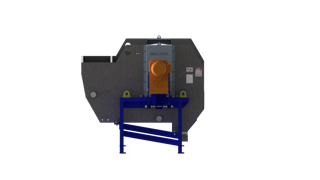

We offer the WLIMS in different configurations to suit the process and design requirements

- Back-to-back design incorporating a common

manifold and concentrate launder. - Combination of various tank and magnetic circuit designs on a single frame.

Design

Features

Tank Designs

Tailings Control

MATERIALS OF

CONSTRUCTION

Drum (Vertical

adjustment)

Waste Purge

System

Magnet (Angular

Adjustment)

Water Weir

System

Self Adjusting

Scraper Blade

HDPE Feed

Maniford

Single Side

Greasing Point

Tank Lining

Options

SAFETY FEATURES